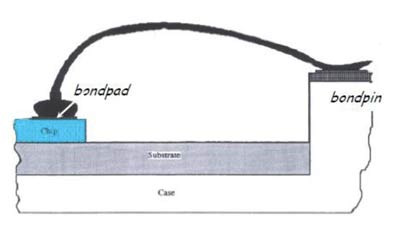

WIRE-BONDING

Method of connection between the pads of the circuit and the pins of the encapsulation employing conductive wires (usually aluminum or gold).

WIRE-BONDING EQUIPMENT

SEMI AUTOMATIC WIRE BONDING TPT HB16

AUTOMATIC WIRE BONDING

TPT HB16

Thermosonic WireBonder

HB16 is a manual/semiautomatic thermosonic wire bonder for Wedge bonding, Ball bonding andBall Bumping. This wire-bonder counts with Motorized Z and Y-Axis and more than 100 Program Storage Capacities and is ideal for laboratories, pilots, and small-scale production lines.

Bonding Methode:

Wedge-Wedge, Ball-Wedge, Ribbon- & Bumb – bonding

Gold wire diameter:

17 – 75µm (0,7 -3mil)

Aluminium wire diameter:

17 – 75µm (0,7 – 3mil)

Ribbon size:

max. 25 x 250 µm (1 x 10 mil)

Ultrasonic system:

63.3 kHz Transducer PLL Control

Utrasonic power:

0–10 Watt Output

Bond time:

0-20000 msec.

Bond force:

5 – 150 cN (350 cN option)

Bonding tool:

1.58 Ø 19 mm length (0.0624” x 0.750”)

Deep-Access:

Wedge16 mm /Ball13 mm

Bond Arm Length:

165 mm