ALIGNMENT & PIGTAILING

The alignment between different optical components or devices (sources and the optical fibers, waveguides, or photodetectors) is one of the most critical performance factors (optical losses) and final circuit operation. In the case of alignment of single-mode fiber, the precision between transmitter and receiver must be less than 1 micron. The transversal alignment must be carried out in the plane perpendicular to the coupling direction (XY plane for horizontal coupling and XZ plane for vertical coupling). Angular alignment is also essential, especially critical in the case of fiber arrays.

ALIGNMENT & PIGTAILING EQUIPMENT

MICOS SF-3000BS ALIGNMENT BENCH

SPLICER FUIJIKURA (PM FIBERS)

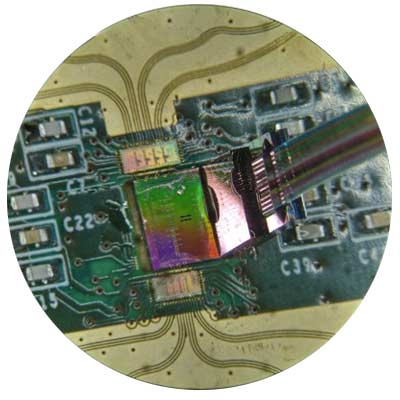

MICOS SF3000BS

The alignment system is semi-automatic equipment for pigtailing and testing optical components. Based on Micos’s Spacefab SF-3000 positioning system, the equipment has been designed for fiber to fiber, fiber waveguide (Edge coupling or grating coupling), and fiber laser diode alignments. The machine incorporated a UV and thermal system for the curating process. The component holders use mechanical clamping and a vacuum system interface. The holders are heated to typically 120ºC.

Degrees of freedom:

6 degres/arm

Linear Travel Ranges:

X: 50 mm

Y: 12.7mm

Z: 100mm

Rotation travel ranges:

Rx, Ry, Rz: up 10°

Velocity Range:

linear: 0.01 … 10 m/sec

Rot: 0.01 … 10°/sec

Bidirectional Repeatability:

linear: ±0.5µm

Rot: ± 20µrad

θ-axis:

Maximum rotating angle: 380 deg.

Thermal and UV Cure Epoxy System

SPLICER FUIJIKURA (PM FIBERS)

The dicing saw DAD3350 can cut the next materials: glass, Si, SOI, Silica glass, Al, and AlNi. The equipment supports for blades of up to Φ5 inches. This equipment has a spindle front-section support structure, which prevents heat shrinkage and vibration.